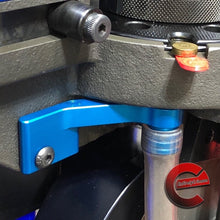

Billet Aluminum Spend Primer Chute for the Dillon Precision CP-2000, RL-1100 and Super 1050 progressive reloading presses. This is also compatible with some but not all RL-1050, see pictures. Other versions are available for each of the other presses.

Funnel your spent primers into a larger container under your bench and save them for recycle (primers are brass). Less interruptions while reloading because you won't need to empty the little plastic bin that comes with the press.

Please watch EC's YouTube install video, "Installing EC’s Spent primer chute on Dillon 1050 1100 and 2000"

Replaces the plastic OEM bin and bracket.

Reuse the original 10-24 X3/8” screw from the OEM spent primer bin bracket to install this chute. The slot for the screw allows adjusting funnel to position against the press to keep it in position. The funnel will be offset slightly under the spent primer hole in the press deck, not fit directly under the hole. Push the chute to the right and toward the back of the press to be as aligned as possible with the drop hole before tightening the screw. Due to the press being cast, there are slight deviations from one to another and there will usually be a bit of a gap above this spent primer chute when it positioned properly. Often there is also a slight gap behind the flat area behind the screw.

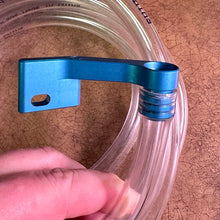

Tubing is sold separately, click HERE to add to your order. Spent Primer Chute Tubing is sold by the foot. The 5/16"ID (9/16"OD) size fits snugly on spent primer chutes without the need for hose clamps. Order the number of feet (12") you need. If you need 4 feet (48") order quantity of 4.CNC made in the USA from billet 6061 aluminum. Anodized colors add durability, improve finish, and increase cost. Raw finish is unpolished and straight off the machine (will have machining tool marks).